DYNAMIC MATERIAL & COMPONENT TESTING

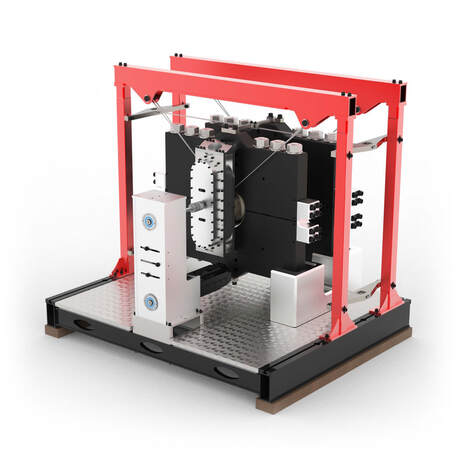

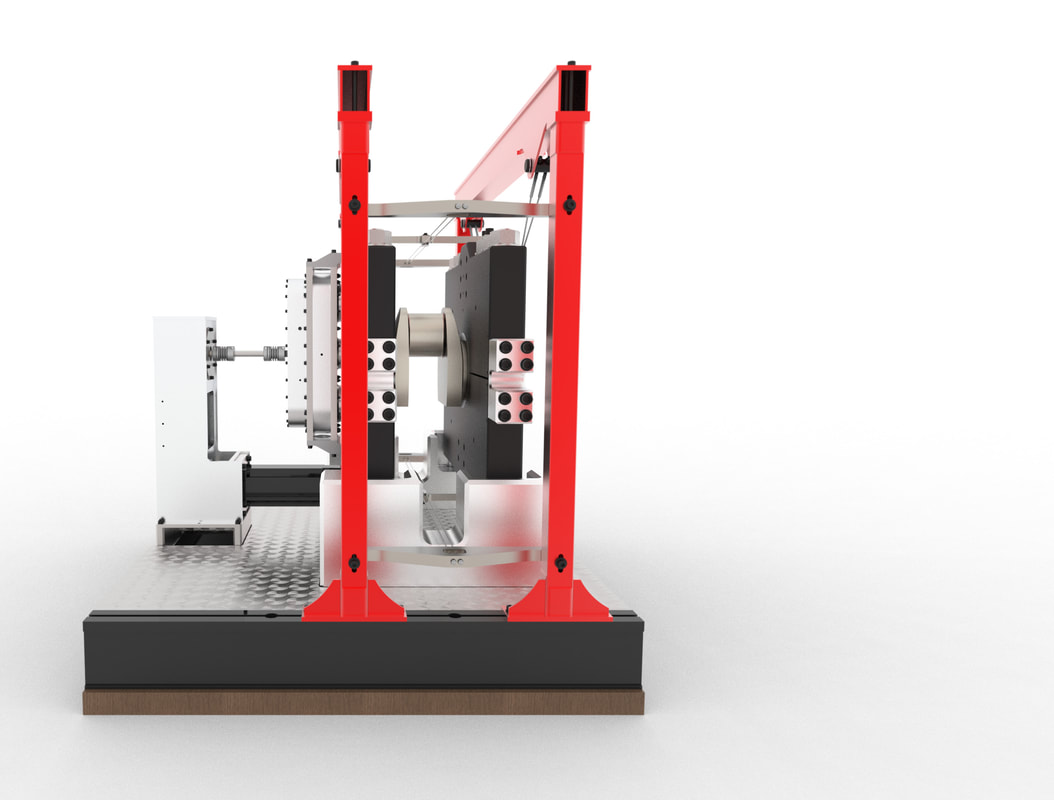

Rail Industry - Wheelset: Axle fatigue testbed with combined torsion and bending load.

In Partnership with PRISMA Engineering, we are mostly tackling the big jobs for bending and torsion fatigue loads...

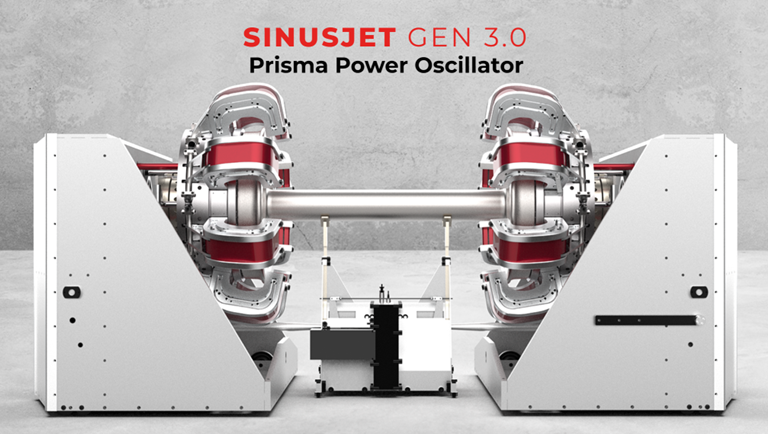

PRISMA's Know-How is rooted in over 25 years of experience in Finite Element Analysis and over 18 years of resonance testbed production. The modular, electro-motoric drive systems allow for high flexibility for custom test applications, such as heavy-duty crankshafts (up to 500mm journal diameter & 4000kNm torque), drive shafts,

cam shafts, rail axles,...

By eliminating dynamic load transfer into the environment, the PRISMA testbeds do not require a foundation. The light weight and very compact design delivers unmatched test frequencies, thereby reducing your test time and costs.

Heavy Duty Industry - Crankshaft: PRISMA SINUSJET CTS for torsion or bending fatigue.